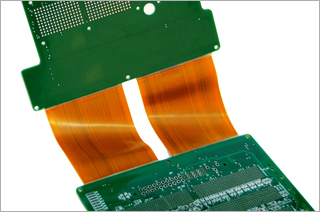

rigid-flex PCB

THE SOLUTION TO YOUR SPACE CONSTRAINTS

Conventional connection systems often occupy an important space available recessed volume and thus are not always the best solution. With the trend towards miniaturization, the use of printed circuit allowing assembly in three dimensions and thus exploiting available space optimally is increasingly appreciated.

Conventional connection systems often occupy an important space available recessed volume and thus are not always the best solution. With the trend towards miniaturization, the use of printed circuit allowing assembly in three dimensions and thus exploiting available space optimally is increasingly appreciated.

The rigid-flex printed circuit is a combination of rigid standards PCB and flexible PCB, having the advantages of each one and bringing the solution to that need space and reliability.

Do you have space constraints? specific requirements to conform to shapes out of the ordinary? The rigid flex printed circuits meet your needs that meet the most stringent constraints.

ADVANTAGES

- Space saving: More components to save space

- Greater reliability: removing connectors, reducing the number of parts, limitation of wired interconnections

- Cost Reduction: integration flexibility, simplification of assembly steps

APPLICATION AREAS

Typical areas of application of the rigid flexible technology can be found in industrial, automotive, aerospace and medical technology. It is suitable for sensors, compact electronic products ...

our expertise

With expertise in the rigid flexible PCB circuits, the PCB Layout Design team will offer you a solution tailored to your situation and your requirements, complying with ISO and UL standards.

CHARACTERISTICs

- base support: standard FR4 multilayer (4 to 20)

- flexible part: polyimide

- Finish: HAL SnPb, HAL Lead Free, Sn chimique, NI/AU chimique et électrolytique, OSP

- Drilling Minimum: 75 microns by 150 microns and laser drilling blind holes in traditional and buried (circuits High Density Interconnect)